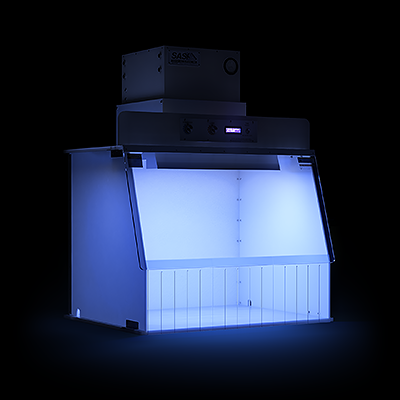

Portable Clean Room

The Portable Clean Room is a compact positive pressure system that provides an exceptionally clean laminar airflow inside the hood. This system utilizes a dual-stage (single for PCR2) filtration process which consists of a MERV8 pre-filter and a HEPA filter with an efficiency rating of up to 99.97% efficient on particles 0.3 micrometers and larger. For applications requiring a higher efficiency, an ULPA filter is available with an efficiency rating of up to 99.9995% at 0.12 micrometers.

Traditionally, companies that desired a clean sterile workspace would have to convert an entire room into a HEPA-filtered positive pressure area and end up spending tens of thousands of dollars and taking up excess room. However, our portable clean rooms are designed to be cost-saving, by offering a compact solution that requires very little space and as much mobility as needed.

12" Portable Clean Room

Model # SS-XXX-XXX

Unit Configurations Quick Compare

Additional Configurations

What is a Portable Cleanroom?

A Portable Cleanroom is a compact positive-pressure system that provides an exceptionally clean laminar (constant, nonturbulent) airflow inside the hood. Typically, a portable cleanroom is used in laboratory, medical, biological, electronics, food and beverage, and scientific applications and offers the ability to be more modular, and mobile than a typical cleanroom where a full room is converted into a controlled environment.

A cleanroom is a designated space or room where alterations are made in order to reduce/remove contamination of particulates, fumes, vapors, and toxins, as well as control the environment's temperature, allotted air pressure (or fan velocity), and room humidity.

What makes a Portable Cleanroom effective?

A key element in making a cleanroom effective is utilizing a HEPA ( high-efficiency particulate air) filter to trap particles down to 0.3 microns with 99.97% efficiency. The air pushed (or pulled) into a cleanroom is passed through the HEPA filter and provides a cleaner atmosphere for the application to be performed in and in the most strenuous cases, a ULPA (ultra-low particulate air) filter can capture particulates down to 0.12 microns with 99.9995% efficiency.

Benefits of a Portable Cleanroom

- ISO Class 5 Cleanroom - reduced contamination in the working environment

- Free-standing, modularity

- Minimal maintenance

- Modifications, customization available

- Compliance with government regulations

- Controlled environment to remove outside tampering

Portable Clean Room Models

Generation I

The original Portable Cleanroom – Generation I offers a simple ON/OFF operation and provides dependable and effective protection for your application. This economical unit helps your facility implement a cleanroom environment without a large investment.

Generation II

This upgraded version, Generation II, offers improved functions, design, and fan system. The front-facing variable speed controller allows the operator to easily adjust the fan speeds to suit their application. The running indicator light informs the user that the system is running. The improved design and fan system have increased the airflow and enhanced the system’s efficiency. Also, this new design allows operators to PAO test to check the filter for leaks and approve the device for certifications such as USP 797.

What is the Classification of a Portable Cleanroom?

Cleanroom classifications are defined simply by how clean the air in the room is. Federal Standard (FS) 209 (A - E) classifies a cleanroom as dependent on the number of particles in a working environment's air. More accurately, 'Cleanroom classification standards FS 209E and ISO 14644-1' require a particle count measurement and calculation in order to fully classify the "cleanliness" of an environment.

ISO 14644-1 Cleanroom Standards

| Class | maximum particles/m3 | FED STD 209E equivalent |

|||||

| >=0.1 µm | >=0.2 µm | >=0.3 µm | >=0.5 µm | >=1 µm | >=5 µm | ||

| ISO 1 | 10 | 2 | |||||

| ISO 2 | 100 | 24 | 10 | 4 | |||

| ISO 3 | 1,000 | 237 | 102 | 35 | 8 | Class 1 | |

| ISO 4 | 10,000 | 2,370 | 1,020 | 352 | 83 | Class 10 | |

| ISO 5 | 100,000 | 23,700 | 10,200 | 3,520 | 832 | 29 | Class 100 |

| ISO 6 | 1,000,000 | 237,000 | 102,000 | 35,200 | 8,320 | 293 | Class 1,000 |

| ISO 7 | 352,000 | 83,200 | 2,930 | Class 10,000 | |||

| ISO 8 | 3,520,000 | 832,000 | 29,300 | Class 100,000 | |||

| ISO 9 | 35,200,000 | 8,320,000 | 293,000 | Room Air | |||

BS 5295 Cleanroom Standards

| maximum particles/m3 | |||||

| Class | >=0.5 µm | >=1 µm | >=5 µm | >=10 µm | >=25 µm |

| Class 1 | 3,000 | 0 | 0 | 0 | |

| Class 2 | 300,000 | 2,000 | 30 | ||

| Class 3 | 1,000,000 | 20,000 | 4,000 | 300 | |

| Class 4 | 20,000 | 40,000 | 4,000 | ||

* At Sentry Air Systems, our portable cleanrooms operate at an ISO 5 classification.

Portable Cleanroom Safety Considerations

The safe operation of your cleanroom is critical to protecting your application, staff, and anyone around it. A portable cleanroom should only be considered if safety measures and protocols are implemented and will be enforced by a safety engineer, or manager on hand. A few safety measurements that should be considered are:

- They should be visually inspected frequently

- Pedestrian traffic in front of the cleanroom should be limited

- Any bulky equipment should be placed at the rear of the hood

- To allow for airflow, large equipment should be raised at least 2” off the surface

- If your cleanroom is used often, a regular cleaning schedule should be established

12in. Portable Clean Room

Product Video

Hood Dimensions:

- O.D.: 10.5"D x 12.5" W x 15"H

- I.D.: 10"D x 12"W x 10"H

Hood Material:

- Sides: .250" White Acrylic

- Base: .500" White High Density Polyethylene

- Top: .500" Clear Polycarbonate

Front Windows:

0.250" Clear Polycarbonate

Total Weight:

Approx. 35 lbs.

Blower Dimensions:

10.5" L x 8" W x 8.5" H

Motor:

Fractional Horsepower

Electrical:

115/1/60, .3 amps

220/1/50, .2 amps

Sound Level:

55 dba @ 3 ft. from hood inlet

Max Operating Temperature:

Not to exceed 170 degrees Fahrenheit

Warranty:

Limited two-year warranty from date of shipment on defects due to materials or workmanship.

Patented Design:

U.S. PATENT #5,843,197

Product Video

Hood Dimensions:

- O.D: 19"D x 20" W x 24"H

- 18"D x 18"W x 15.5"H

Hood Material:

- Polyethylene Terephthalate Glycol (PETG)

- Base: 0.250" Clear Polycarbonate

Blower Dimensions:

7.5" L x 7.5" W x 8.5" H

Total Weight:

Approx. 11 lbs.

Motor:

Fractional Horsepower

Electrical:

115/1/60, .3 amps

220/1/50, .2 amps

Sound Level:

Approx. 55 dba @ 3' from hood inlet

Max Operating Temperature:

Not to exceed 170 degrees Fahrenheit

Warranty:

Limited two-year warranty from date of shipment on defects due to materials or workmanship.

Patented Design:

U.S. PATENT #5,843,197

Product Video

Hood Dimensions:

- O.D.: 18.5"D x 20" W x 19"H

- I.D.: 18"D x 18"W x 18"H

Hood Material:

- Sides: .250" White Acrylic

- Base: .500" White High Density Polyethylene

- Top: .500" Clear Polycarbonate

Front Windows:

0.250" Clear Polycarbonate

Blower Dimensions:

10.5" L x 8" W x 8.5" H

Total Weight:

Approx. 35 lbs.

Motor:

Fractional Horsepower

Electrical:

115/1/60, .3 amps

220/1/50, .2 amps

Sound Level:

55 dba @ 3ft. from hood inlet

Max Operating Temperature:

Not to exceed 170 degrees Fahrenheit

Warranty:

Limited two-year warranty from date of shipment on defects due to materials or workmanship.

Patented Design:

U.S. PATENT #5,843,197

Product Video

Hood Dimensions:

- O.D: 24"D x 26"W x 25"H

- I.D.: 23.5"D x 24"W x 24"H

Hood Material:

- Sides: .250" White Acrylic

- Base: .500" White High Density Polyethylene

- Top: .500" Clear Polycarbonate

Front Windows:

0.250" Clear Polycarbonate

Blower Dimensions:

13" L x 13" W x 14.5" H

Total Weight:

Approx. 95 lbs.

Motor:

Fractional Horsepower

Electrical:

115/1/60, 2 amps

220/1/50, .75 amps

Sound Level:

55 dba @ 3ft. from hood inlet

Max Operating Temperature:

Not to exceed 170 degrees Fahrenheit

Warranty:

Limited two-year warranty from date of shipment on defects due to materials or workmanship.

Patented Design:

U.S. PATENT #5,843,197

Product Video

Hood Dimensions:

- O.D: 24"D x 32"W x 25"H

- I.D.: 23.5"D x 30"W x 24"H

Hood Material:

- Sides: .250" White Acrylic

- Base: .500" White High Density Polyethylene

- Top: .500" Clear Polycarbonate

Front Windows:

0.250" Clear Polycarbonate

Blower Dimensions:

13" L x 13" W x 14.5" H

Total Weight:

Approx. 100 lbs.

Motor:

Fractional Horsepower

Electrical:

115/1/60, 2 amps

220/1/50, .75 amps

Sound Level:

Approx. 55 dba @ 3' from hood inlet

Max Operating Temperature:

Not to exceed 170 degrees Fahrenheit

Warranty:

Limited two-year warranty from date of shipment on defects due to materials or workmanship.

Patented Design:

U.S. PATENT #5,843,197

Product Video

Hood Dimensions:

- O.D: 24"D x 42W" x 25"H

- I.D.: 23.5"D x 40"W x 24"H

Hood Material:

- Sides: .250" White Acrylic

- Base: .500" White High Density Polyethylene

- Top: .500" Clear Polycarbonate

Front Windows:

0.250" Clear Polycarbonate

Blower Dimensions:

13" L x 13" W x 14.5" H

Total Weight:

Approx. 115 lbs.

Motor:

Fractional Horsepower

Electrical:

115/1/60, 2 amps

220/1/50, .75 amps

Sound Level:

Approx. 55 dba @ 3' from hood inlet

Max Operating Temperature:

Not to exceed 170 degrees Fahrenheit

Warranty:

Limited two-year warranty from date of shipment on defects due to materials or workmanship.

Patented Design:

U.S. PATENT #5,843,197

Quick Compare

|

Generation I |

Generation II |

Variable Speed Controller Standard |

No |

Yes |

Easy Filter Change |

Yes |

Yes |

Running Indicator Light |

No |

Yes |

Airflow |

Up to 350 CFM (HEPA) |

50 – 400 CFM (HEPA) |

Prefilter |

Yes – MERV 8 |

No |

Main Filters |

HEPA or ULPA |

HEPA or ULPA |

Electrical |

115/1/60, 2 amps |

115/1/60. 1.65 amps |

Sound Level |

55 dba |

50 - 65 dba |

ISO Classification |

Up to ISO Class 5 |

Up to ISO Class 5 |

Portable Clean Room with UVC Controls

SAS Portable Clean Rooms with UVC utilize the documented power of UV lights to actively disenfect clean room environments from pathogens, germs, viruses and other hazardous bacteria. Offering a simple user interface, the Portable Clean Room with UVC is essential in protecting workers from the environment they are working with, and the respirable hazards they may be exposed to.

Accessories

Resources

- Clean Room Hoods Applications

- Testimonial: Research in the Peruvian Rainforest

- Testimonial: Stem Cell Therapy

- Testimonial: Assembly of Projection Lenses in Portable Clean Rooms

- Testimonial: Vertical Laminar Flow Hood for Fungal Cell Culture

GSA

- GSA Contract #: GS-07F-0039X Category 66: SCIENTIFIC EQUIPMENT and SERVICES

- SIN 66-147: Laboratory Fume Hoods, Accessories & Options

- You will find the GSA logo on eligible product pages within our website. To obtain a Quote or receive additional information on these products, either:

- Fill out our feedback form.

- Visit our company profile in the GSA ELibrary and click on “View Items Available” for an itemized list of available products at GSA Advantage!

Q&A

What is laminar air flow?

Laminar air flow is when a stream of constant air is provided with the same speed and direction, with no crossover of air stream. The Vertical Laminar Flow Hood is rated as an ISO Class 5 clean room cabinet. It protects the process by utilizing a vertical laminar flow pattern and dual-stage filtration system that delivers positive-pressure, purified air through a pre-filter and main filter. The main filter is typically either a HEPA or ULPA filter depending on the efficiency desired. The HEPA filter is up to 99.97% efficient on particles 0.3 microns and larger, while the ULPA filter is up to 99.9995% efficient on particles 0.12 microns and larger.

Made in the USA

Made in the USA